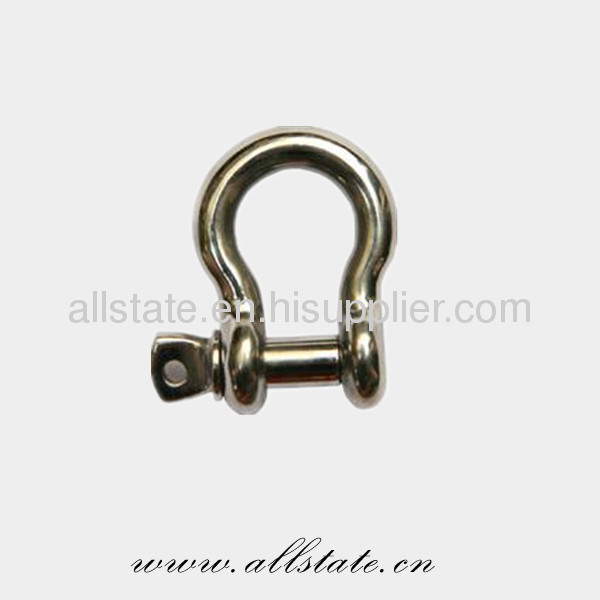

Bolt type bow shackle

| Price: |

1.0~50.0 USD |

| Payment Terms: |

T/T,L/C,D/A,D/P |

| Place of Origin: |

Shaanxi, China (Mainland) |

Product Detail

Model No.:

As per your dwg

Production Capacity:

5000 Ton/Tons / Year

Delivery Date:

Delivery time: about 30 day...

Brand Name:

Aosite

Material:

Stainless Steel

Prodution Runs:

Drop Forged, Upset Forged a...

Certification:

SGS & ISO

OEM:

Accepted

Means of Transport:

Ocean,Air

Packing:

To be packed in wooden case...

Place of Origin:

Shaanxi, China (Mainland)

Model Number:

Aosite

Useful:

Connection

Surface Treatment:

Hot Dipped Galvanized, Elec...

Specification:

Checking The Picture

Bow Shackle With Safety Bolt

1.All Kinds Of Shackles

2.Excellent Quality & Fair Price

3.Professional Manufacturer & Trader

| Bow Shackle With Safety Bolt

Shackles Information

Shackles are U-shaped pieces of metal secured with a pin or bolt across the opening, or hinged metal loops that are secured with a quick-release locking mechanism.

Types of Schackles

There are three basic types of shackles. All meet or exceed U.S. Federal Specification RRC-271D, "Chains and Attachments: Welded and Weldless", and are made of alloy steel or carbon steel. They are available in painted, galvanized or self-colored finishes and use quenched or tempered pins.

Class 1 shackles pass a rounded pin through holes at the base of the shackle. A spring-actuated cotter pin or hair pin holds the butt end of the shackle in place. Class 2 shackles use screw-pins that pass through an opening on one only side of the shackle. The pins use a key-like design and exhibit extreme deformation before failure. Class 3 shackles have safety anchors or chains that are held in place with a nut and bolt on opposite ends of the pin.

•All shackles meet or exceed Federal Specification RRC-271D

•Working Load Limit and traceability codes shown as permanent marking on body and pin

•Available in painted, galvanized and self-colored finishes (Dacromate coating upon special request only)

•All shackles have alloy quenched and tempered pins

•Shackles made from technically advanced microalloy material

•Load break tests consistently show microalloy out performs quenched and tempered carbon material

•Shock load testing of assemblies at -30ºF consistently demonstrate microalloy outperforms quenched and tempered carbon material*

•Shackles exhibit extreme deformation before failure*

•Special testing and certification including magnetic particle, proof load, and fatigue test available upon request at time of order

•Special products engineering available to fit your special lifting, tie down, and pulling needs

•Design factor 6:1 |

|---|

We hope for long-term business cooperation with you in the near future!

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com