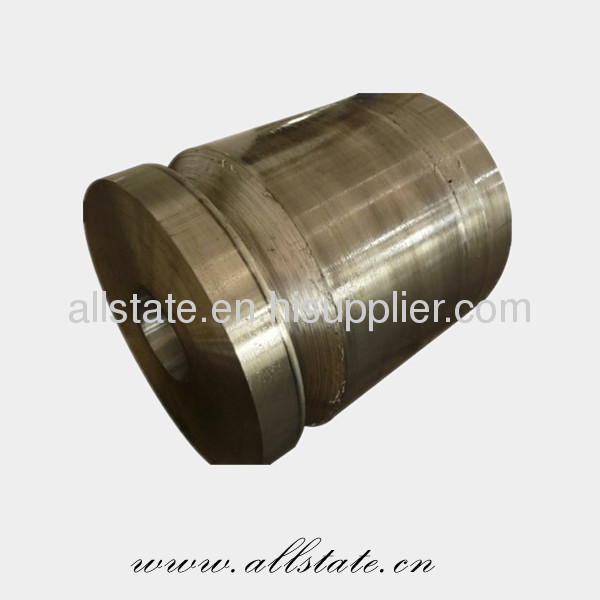

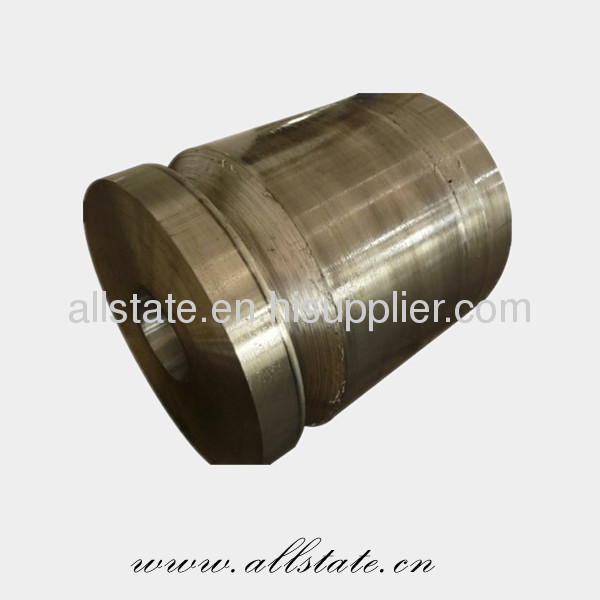

Die Forging Hammer Wide Usage

| Price: |

10.0~60.0 USD |

| Payment Terms: |

T/T,L/C,D/A,D/P |

| Place of Origin: |

Shaanxi, China (Mainland) |

Product Detail

Model No.:

Aosite

Production Capacity:

300000 Piece/Pieces / Mont...

Delivery Date:

one month after order

Place of Origin:

Shaanxi, China (Mainland)

Material:

Stainless steel

Certificate:

ISO & SGS

OEM:

Customised

Means of Transport:

Ocean,Air

Packing:

To be packed in wooden case...

Brand Name:

Aosite

Application:

Various Industries

Dimensions:

As your requst

Packaging Detail:

Sea-worthy Case

Shape:

Wedge

Die Forging Block Wide Usage

1.Forging

2.Galvanizing

3.More Durable

Die Forging Block Wide Usage

Forgings are generally used in applications where the high integrity of the part is of utmost importance. They are used primarily for structural components such as the intake of Gas turbine engines where light weight is crucial. In automotive applications, forged components are commonly found at points of shock and stress.

|

High Strength |

| In making a forging, the metal is worked twice under tremendous pressures. First during rod extrusion, drawing or rolling and then during forging. The double working under pressure, compacts the metal, and produces a very dense and refined grain or fiber structure. The tensile strength of the parts is thereby increased, and resistance to impact and abrasion is enhanced. |

| Leak Resistance |

| The dense non-porous forged metal permits the designer to specify thinner sections without the risk of leaks. Often, the thinner forged parts result in lighter weight and lower piece cost compared to other manufacturing processes. |

| Close Tolerances |

| A forging produced in a steel die with close tolerances offers several advantages. Overall part dimensions are held closer than in sand casting. Dimensions show minimum variation from part to part allowing for automatic chucking and handling in subsequent operations. The precise designs on the die surface can produce sharp impressions on the forging surface, which is normally not the case with other forming processes. |

| Low Overall Cost |

| Mass production of forged parts lends itself to maximum savings. However, smaller quantities of copper alloy forgings can also prove economical when specific design parameters must be met. These requirements include leak integrity, close tolerances, high strength with low weight, and non-symmetrical shape. |

|

|

Please feel free to contact me!

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com